English

English

English

English

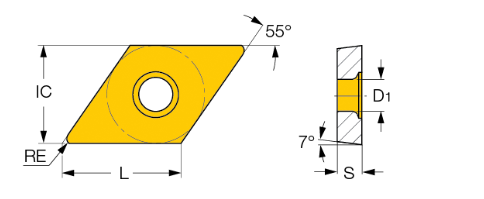

55° rhombic 7° positive flank inserts used for semi-finishing and finish turning. Chip breaking in moderate feed range. Positive rake, low cutting forces. Used for a wide range of materials including soft and exotic alloys. A tough sub-micron substrate, PVD coated. Suitable for low-to-medium cutting speeds. Developed for machining of heat resistant alloys, austenitic stainless steel and hard steel.

Excellent surface mirror finish. High wear resistance and corrosion resistance. The service life of tungsten carbide is 50 times longer than common steel tools. Reduce mill downtime,high rolling speed,increase productivity. Made from virgin raw materials,a wide range of grade applications,HIP sintering. Good surface finish for rolled product. Good wear resistance,high strength and toughness,excellent red hardness and heat fatigue resistance. Non-destructive ultrasonic flaw detection,without sand hole,pore,cracks and inclusions.TurningTurning

CNC Turning Insert-3

CNC Turning Insert-2

CNC Turning Insert-1

Products surface finish machining & polishing;Maximize products' value, reduce your cost;

Customized training course according to your demand;Help you to improve productivity and reduce the cost;

According to your required specification, we can manufacture various non-standard cemented carbide products to meet your special demand;

We make stress elimination for each product, improving products' performance andprolong product Service Life;

Provide using advise for cemented carbide products;Grade choosing service;Work out the best scheme on the scene;

Responding mechanisms within 24 hours;Provide timely remote technical support.;

Just feel free to contact us,we will try our best to service you.

Need more detailed information about this product ?Just contact us now!

Subscribe below to get regular updates from HengCheng!

search

Shanghai Hengcheng cemented carbide Co., Ltd

Room 1002, building 2, Huayi Plaza, 2020 Zhongshan West Road, Shanghai

Telephone: +86 21-6119 8069

General Manager:

market@hccarbide.com