English

English

English

English

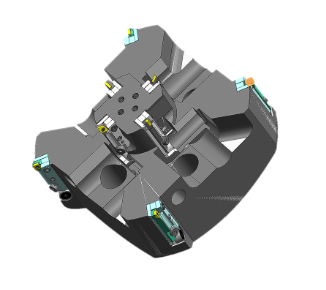

Motor hole machining, rough machining D220 six teeth, D72 two teeth; finishing D220 four teeth, D72 two teeth, finishing single side margin 0.2mm, HSK100 tool holder

+ aluminum alloy tool body + μm level fine-tuning tool holder .

Processing difficulties

The tool diameter is large and the tool weight needs to be controlled

There is a root cleaning groove at the bottom of the D72 diameter hole

D72 cylindricity 0.008

D72 and D220 coaxiality 0.025

Roughness Ra0.8

D72 has holes

D220 Intermittent machining

processing method

High-strength aluminum alloy body to control overall tool weight

D72 non-standard PCD forming blade

D72 and D220 simultaneous finishing

μm-level precision boring tool holder accurately adjusts the runout of the blade and the diameter of the tool

Laser-cut PCD blade edge ensures perfect edge quality

Processing examples

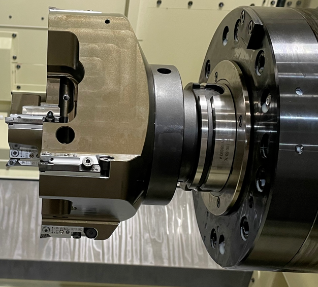

Part name: Motor housing

Part material: ADC12 cast aluminum alloy

Machine tool: Makino Horizontal Plus (HSK100 tool holder)

Cooling method: cooling inside the machine tool

Processing type: compound boring

Cutting parameters: vc=1660m/min, fz=0.1mm/r

Subscribe below to get regular updates from HengCheng!

search

Shanghai Hengcheng cemented carbide Co., Ltd

Room 1002, building 2, Huayi Plaza, 2020 Zhongshan West Road, Shanghai

Telephone: +86 21-6119 8069

General Manager:

market@hccarbide.com