English

English

English

English

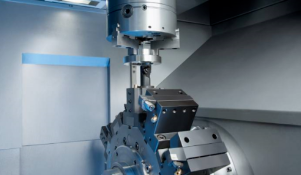

As a typical product of the EMAG inverted turning center, the VL6 machine tool is suitable for the combined processing of turning, milling and drilling of disc parts with a diameter of <300mm, including the main reduction gear and intermediate shaft gear in the drive motor of new energy vehicles.

Processing difficulties

High-precision dimensional and geometric tolerance requirements

Efficient parts processing cycle time

processing method

Relying on excellent machine tool rigidity, unique inverted structural design, and high stability, VL6 can stably achieve gear inner diameters within 120±0.01mm and inner diameter cylindricity

within 0.008mm.

Each VL series machine tool is a complete production unit with a unique inverted spindle structure. In addition to processing workpieces, the spindle is also used for automated external

loading and unloading, which saves expenses, floor space and unnecessary External automation equipment, high efficiency and high economy.

Processing examples

Processed parts: main reduction gear

Processing machine tool: VL6

Processing type: hard turning

60 seconds to complete hard turning of gear end face and inner hole (including loading and unloading)

Subscribe below to get regular updates from HengCheng!

search

Shanghai Hengcheng cemented carbide Co., Ltd

Room 1002, building 2, Huayi Plaza, 2020 Zhongshan West Road, Shanghai

Telephone: +86 21-6119 8069

General Manager:

market@hccarbide.com