English

English

English

English

1. What are small parts?

Small parts generally refer to various types of small hardware parts, mostly made of non-ferrous metals such as stainless steel, aluminum alloys and copper alloys. They are

widely used in automobiles, aerospace, instrumentation, abrasives, daily necessities, electronic equipment and other industries. With the development of science and

technology, parts in various industries tend to be smaller and smaller. More and more small parts are produced. At the same time, more and more difficult-to-chip materials

are processed in small parts. The demand for tool performance for small parts processing is getting higher and higher. Come higher and higher.

The processing characteristics of small parts include fewer processes, fast cycle time, compact structure of processing equipment, small space, and very high requirements for

tool chip breaking. Small parts play a very important role in various types of mechanical equipment and consume a lot of money, such as:

2. Production line

The CNC centering machine has the combined function of turning and milling, and is particularly suitable for large-volume, multi-variety, and high-precision processing

tasks of slender shafts and small complex rotating parts. It focuses on the high-efficiency, high-precision mass production of small parts, and various technologies.

The parameters and performance indicators have reached the advanced level of similar international machine tools. It can process small precision parts and complex

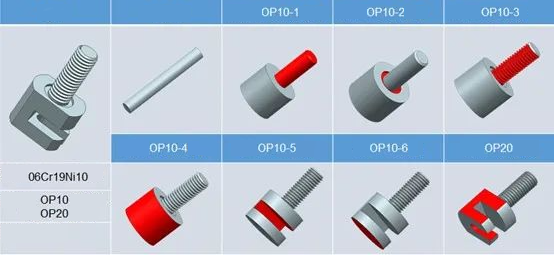

composite parts with diameters ranging from Φ2 to Φ15, Φ4 to Φ20 and other specifications. Each model and specification is divided into the following types.

Basic type - capable of turning outer circles, arcs, cones, spherical surfaces, end faces, boring inner holes, turning internal and external metric/imperial threads, grooving,

drilling, knurling, push-pull grooves, rigid tapping and other processes. Composite type - Equipped with a system with side processing function, in addition to being able

to process the above types and material ranges, it can also be adapted to composite processing on the side. Such as polyhedron milling, slot milling, textured chute milling,

curved surface arc milling, side drilling and rigid tapping, lettering and other complex processing processes.

Craftsmanship and Tools

Problem: The size of the workpiece processed by small parts is relatively small, and the machining allowance is small. Elongated iron filings are easily formed during

processing, causing the iron filings to wrap around the tool handle. The machine needs to be shut down to manually remove the iron filings wrapped around the tool handle,

causing the machine tool to stop. If the time is too long, the efficiency will be reduced.

Countermeasures: Hengcheng launched three-axis chip breakers HF, HQ, and HF to improve chip handling, and further improved the curling of iron chips through mirror

processing to avoid iron chip entanglement.

Problem: The tool space for processing small parts is small, and the blade cannot be changed directly on the machine tool. To change the tool, tool setting is also required,

which takes a long time and reduces the working time of the machine.

Countermeasures: Hengcheng launched the HZ tool holder series, which has an exclusive HZ adjustment structure, which can achieve high-precision positioning, reduce tool

changing time, increase machine tool working time, and reduce overall costs.

Problem: The tool space for processing small parts is small, and the blade cannot be replaced directly on the machine tool. This takes a long time and reduces the working

time of the machine.

Countermeasures: Hengcheng launched the HZ tool holder PLUS series. When the tool holder does not need to be moved, the blade can be directly replaced. It is equipped

with an exclusive HZ adjustment structure, which can achieve high-precision positioning, reduce tool change time, increase machine tool working time, and reduce overall cost.

Problem: With the popularity of hard-to-chip materials such as heat-resistant alloys, work hardening and strong tool sticking are common in machining difficult-to-chip

materials. Especially titanium alloys have poor rigidity and are easy to deform, making them unsuitable for making slender rods and thin rods. For wall parts, the rebound

amount of the machined surface during cutting is very large, about 2 to 3 times that of stainless steel, causing severe friction, adhesion, and bonding wear on the tool

flank surface, resulting in difficulty in processing and poor chip removal by the tool, resulting in Tool wear and breakage.

Countermeasures: Hengcheng launched negative-angle blades for small parts, which are as sharp as positive-angle blades and doubled the number of tips, reducing tool

costs. At the same time, Hengcheng launched PVD-coated PR1425 special material for small parts for high-speed processing, and it was mirror-finished. Processing, it can

effectively reduce the sticking effect of hard-to-chip materials, making it easier to discharge the cutting. It not only ensures the sharpness comparable to that of a

positive-angle blade, but also ensures high cost performance.

Subscribe below to get regular updates from HengCheng!

search

Shanghai Hengcheng cemented carbide Co., Ltd

Room 1002, building 2, Huayi Plaza, 2020 Zhongshan West Road, Shanghai

Telephone: +86 21-6119 8069

General Manager:

market@hccarbide.com